1510 W. Drake Drive, Tempe, Arizona USA 85283

info@vanhornaviation.com

Van Horn Aviation | Composite Rotor Blades

Van Horn Aviation | Composite Rotor Blades

Inconel Approved for VHA Abrasion Strips

VHA’s 206B/L main rotor blades were initially designed with two or three overlapping abrasion strips covering the the leading edge. The inboard and middle abrasion strips were made from roll-formed stainless steel; the outboard tip nickel abrasion strip is electroformed in-house at VHA.

These abrasion strips are non-structural components of the main rotor blade assembly and serve to protect the underlying composite material from impact and erosion damage. The abrasion strips are designed to remain installed and in service even after sustaining damage due to erosion, impact, or cracking as long as no underlying void or debond has occurred (in the case of an impact).

While the main rotor blades’ stainless steel abrasion strips are the same material from the same manufacturer as the abrasion strips on our UH-1 tail rotor blades, which have flown up to 2,500 hours with no cracking, some customers are reporting cracks on their VHA main rotor blades within the first 1,000 hours of flight. The interim solution for these customers is to apply a polyurethane tape across the cracks as specified in Customer Service Specification 501 (CSS-501).

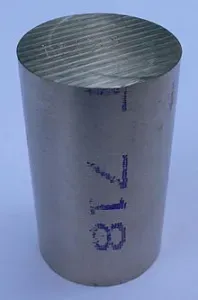

Most of the cracking seemed to occur on one batch of the abrasion strips installed on 206L mains, and we thought it might have been an isolated issue. But then we started receiving reports on 206B mains, so we began looking for a tougher corrosion-resistant material for main rotor blade abrasion strips. We performed several tests with Inconel, a trademarked nickel-chromium alloy used in many aerospace applications, including abrasion strips for various heavy-lift helicopters. Based on these tests and other empirical data, we believe that use of the Inconel will solve the main rotor blade abrasion strip cracking issues.

The FAA approved the use of Inconel as a change to all three main rotor blade STCs (P/N 20631000-101, 20635000-501, and 20633000-101) in late June. Main rotor blades manufactured starting in July 2021 contain Inconel abrasion strips, which should solve future abrasion strip cracking issues. Note that on the 206L main rotor blade (P/N 20633000-101), the inboard abrasion strip has been removed from new production blades to match the 206B main rotor blades.

VHA is currently working with customers who have experienced abrasion strip cracking to replace these strips with Inconel under warranty.

SUBSCRIBE TO VHA'S NEWSLETTER

Thank you for subscribing!

Please try again later.

SITE NAVIGATION

PRODUCTS

All Rights Reserved | Van Horn Aviation

Designed & Managed by www.AdgilityMediaGroup.com