1510 W. Drake Drive, Tempe, Arizona USA 85283

206L Main Rotor Blades

206L Main Rotor Blades

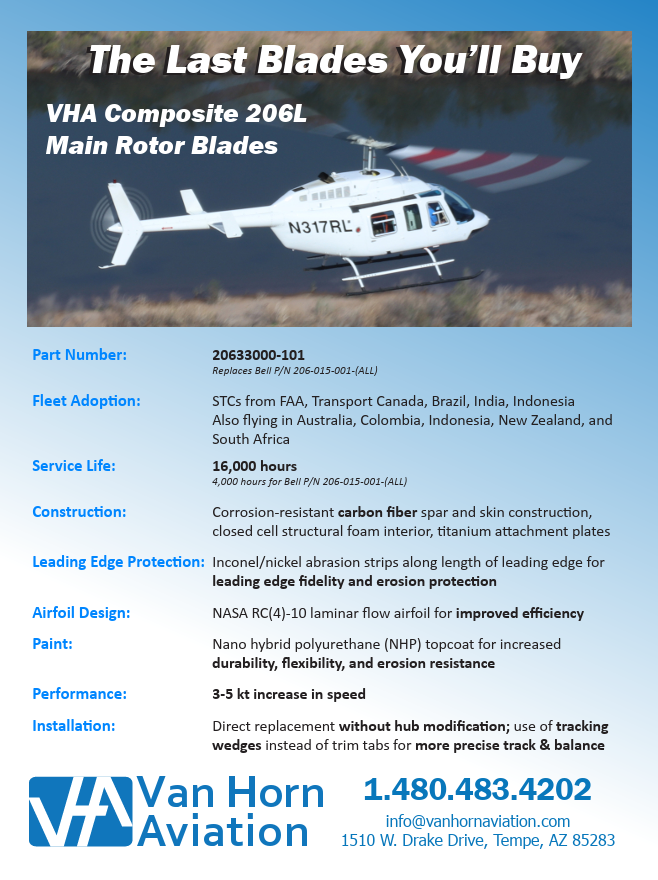

The Last blades you'll NEED TO buy

The VHA 206L LongRanger main rotor blades feature rugged construction and composite materials, including fiberglass root and tip blocks, foam core, carbon fiber spar and skin, and Inconel/nickel abrasion strips. Service life on our 206L main rotor blades is an astonishing 16,000 hours! Unlike the OEM blades that are thrown away at 4,000 hours, VHA blades require a relatively quick inspection and revamp of the metal components and you're back flying again for another 4,000 hours. Repeat 3x and you save about 80% in direct operating costs!

Benefits and Features

As of January 2025, more than 250 sets of our 206L main rotor blades are flying all over the world by single-ship and fleet operators alike. Some operators are reporting speed increases of up to 5 kts (especially when paired with the VHA tail rotor blades), greater fuel efficiency, and ride as smooth or smoother than the OEM blades when flown at speed (above 40 kts). See our Customer Spotlights to read more about what operators are saying about VHA main rotor blades.

The main differences between the 206L and 206B main rotor blades is an additional 22 inches on the 206L blade and design changes to account for the differences in the transmission suspension between the LongRanger and JetRanger (for a complete list of differences, read our

blog post here).

- FAA STC/PMA approved (STC SR02684LA) with STC validations from Canada (STC SH18-69), Brazil (STC 2018S11-11) and India (Letter of Type Acceptance for 206L4 only)

- 16,000-hour service life (4x life of the OEM metal blades)

- In-field inspection and plate replacement every 4,000 hours

- Tracking wedges replace trim tabs for more precise track and balance.

- Efficient NASA RC(4)-10 laminar flow airfoil

- Corrosion-resistant composite materials

- Inconel (nickel-chromium alloy) and electroformed nickel abrasion strips cover the entire length of the leading edge for erosion and lightning strike protection.

- No new equipment needed for installation, tracking or balancing.

206L Main Rotor Blades

Product Information

Dimensions

Length

210.0 inches from tip to end of grip plate

Chord

13.0 inches

Thickness

3.308 inches (at Grip Pads)

Part Number and Pricing Information

The VHA 206L LongRanger main rotor blade is available directly from Van Horn Aviation and our Distributor network.

- Contact Distributors for availability and pricing

- Part number: 20633000-101

- Replaces Bell part numbers: 206-015-001-ALL

Warranty Information

Three-year/3,000 flight-hour warranty against manufacturing and material defects (excludes damage due to erosion)

Blade Track and Balance Information

Our VHA 206L main rotor blades are shipped in balanced pairs. However, static and dynamic balance may be performed in the field in accordance with VMM-MR-206L-501 Instructions for Continued Airworthiness (available on our Documents page). The documents page also contains PDFs of paper charts that can be used to balance VHA 206L main rotor blades.

VIEW MORE

VHA has also published a supplemental document with balance procedures and best practices.

In late 2022, VHA stopped shipping main rotor blades with trim tabs. Part number 20633000-101 Serial Number A281 and higher use tracking wedges as the main source of track adjustment. Please refer to Technical Bulletin TB 20630000-2R3 for detailed information about using tracking wedges.

206L Main Rotor Blades

Related Blog Posts

Contact us to elevate your operations!